Service Bulletins / Maintenance

As the original light hovercraft manufacturer, we at Neoteric value our 40-year reputation for serving our customers with honesty, integrity and a genuine interest in helping you maintain your hovercraft for economic, dependable and long-life operation. Since we will never allow public image to take priority over customer satisfaction and safety, we will not hesitate to make you aware of even the most minor issues with our hovercraft.

In this spirit, please be assured that we will publicize here any issue reported by our customers or learned through continual research and testing by Neoteric engineers, and will provide maintenance instructions to prevent the issue from affecting your hovercraft.

Below you will find Service Bulletins for inspections Neoteric currently recommends as a part of your routine maintenance. Click each recommendation below for complete instructions and photos.

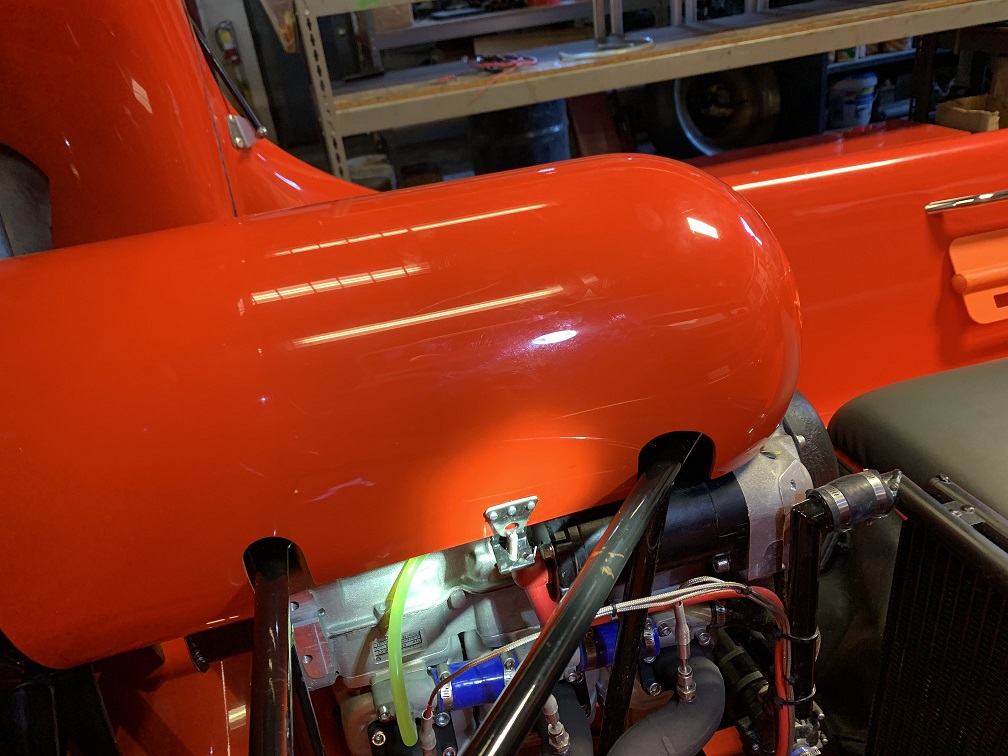

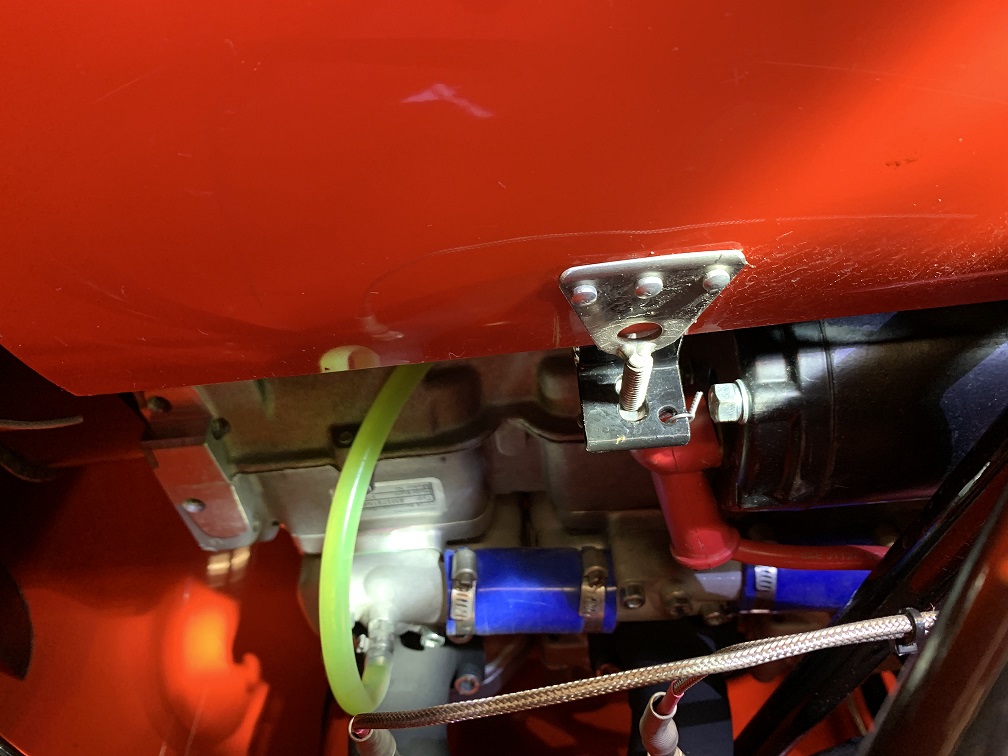

HIGHSPEED CRASH ACCIDENT

March 15, 2024

The resulting damage of hitting an island at high speed after dark. Damage to the craft was minimal as most of the impact energy appears to have been absorbed by the urethane foam in the hull. It appears that this accident was the result of the craft being operated by an inexperienced pilot with approximately 1 hour of piloting experience. A beginner should always practice away from obstacles and should not exceed 25 mph for the first 5 hours.

GAS TANK SENDER DAMAGE

March 15, 2024

After sitting for 9 years without use, this sender was removed. Many of the plastic parts have failed. The pick-up hose is still in good condition. The copper fuel pick-up tube has formed copper sulphate crystals. If these have formed inside the pick-up tube, they will restrict the free flow of fuel so the sender/pick up had to be replaced.

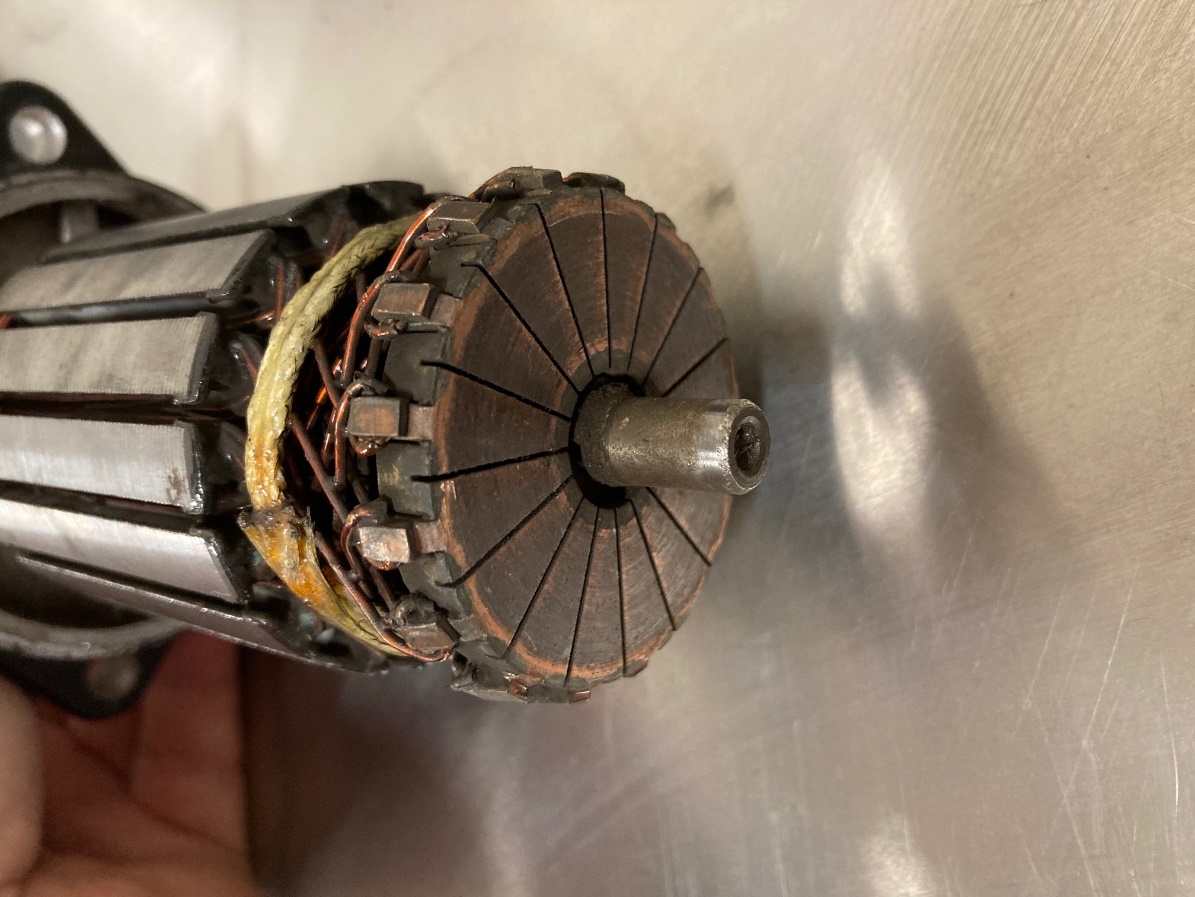

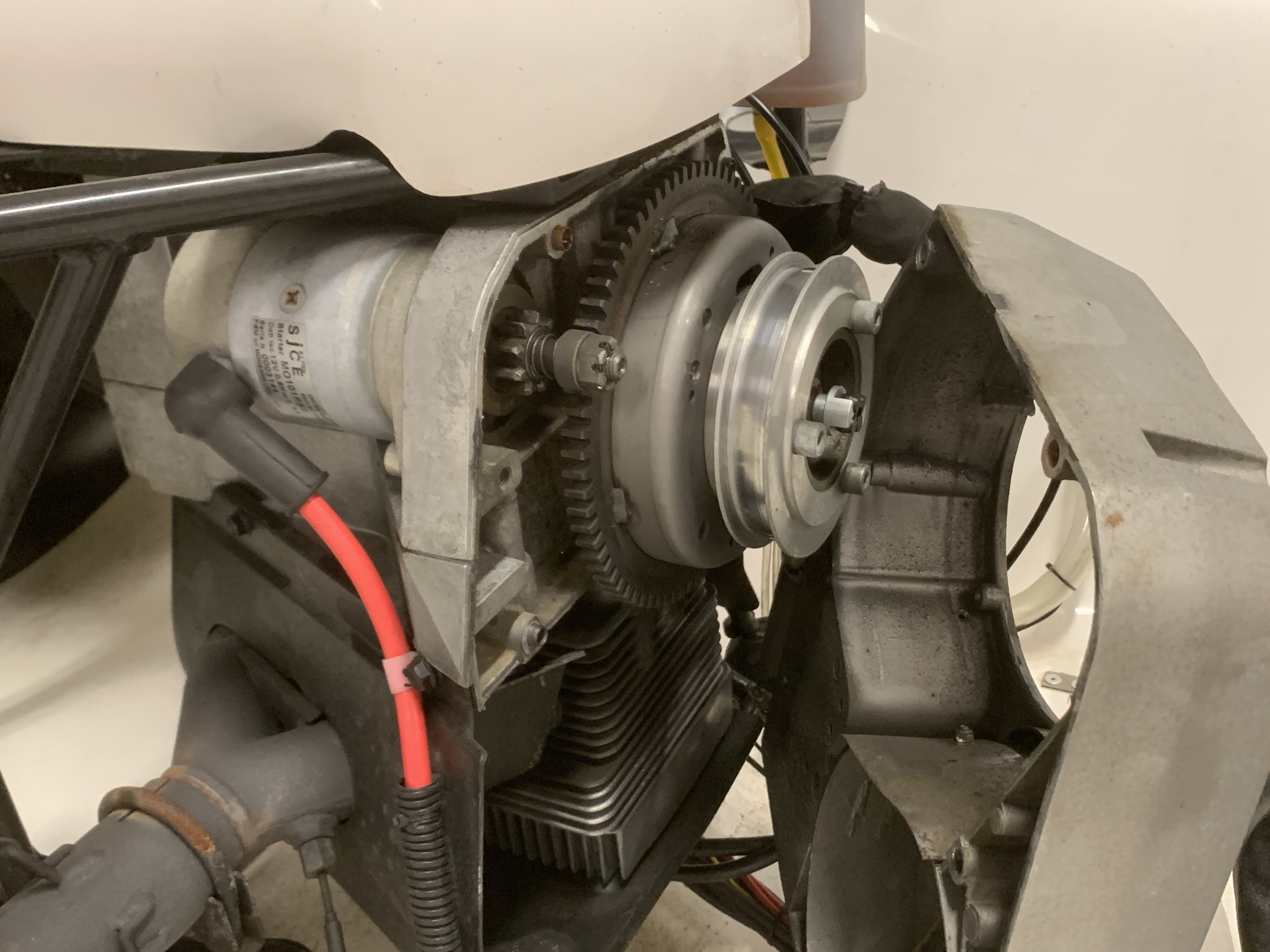

100 HP ELECTRIC STARTER MOTOR FAILURES

May 26, 2022

A Fire department operating a 100 HP engine in fresh water had a starter motor failure after 50 hrs. According to the Hirth dealer, the shaft that rides in the brass bushing at the rear of the starter had worn. This would allow the rotor to be misaligned with the magnets resulting in high electrical current. It also looks like water had entered the starter. There are 3 rubber O rings used to keep water out. There is a thin O ring on each cap and a larger one that presses against the engine block. Make sure the cap O rings are present and not damaged. Make sure all 4 brushes moved freely. (occasionally they stick see the following technical alert). Apply heavy grease to the shaft/bushing. The manufacturer lubricates the bushing with light oil and the heavy grease is much better and will last longer. In future Neoteric will rebuild all new starters during hovercraft manufacturing.

Starter Motors on 100HP Hirth Engine randomly fail. This has happended in less than 1 hour of service. Upon investigation, it appears that the longer power supply wire, feeding one of the 4 brushes, when assembled is too tight, it catches on the brush plastic guide and the brush spring force is insufficient to overcome the brush sliding friction. This holds the brush away from the commutator.

Solution is to open the starter and free up the power cable. Also WD40 all brush sliding surfaces and add grease to the motor shaft bearing.

Contact Neoteric for a specific advice or with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

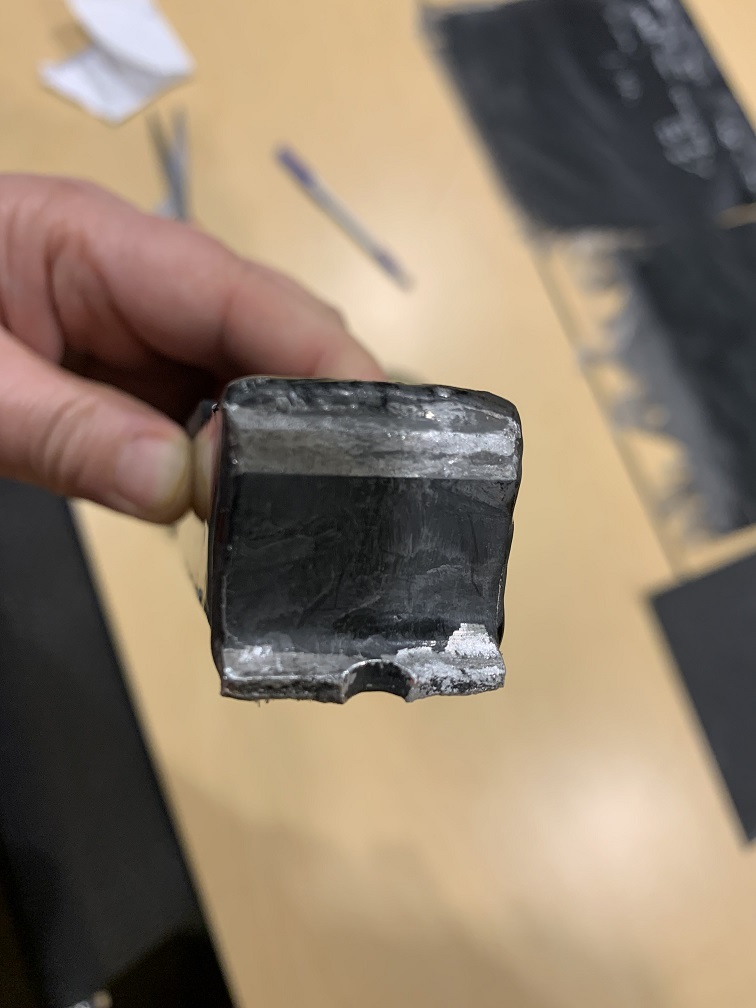

CONSEQUENCE OF ENGINE OVERHEATING

March 18, 2022

Hirth 100 HP 3 cylinder 2 cycle aircraft engines installed in Neoteric Hovercraft can overheat. Excessive water spray which douses the water pump Vee drive belt causes slippage. Also, the belt must be constantly checked for tightness. It should deflect about 1/8 inch when squeezed by hand as hard as possible.

If the belt slips, the water pump slows down and so does the coolant flow rate. This causes the fluid to heat up and boil. The expanding coolant flows into the overflow tank. If this becomes excessive, it can force the tank cap to blown off. Should the engine be operated in this condition, it will overheat. The pistons will expand inside the cylinders. This is followed by piston and ring seizure. Rings can break and score the cylinder wall. Extensive damage results.

The following photograph show typical damage failure from overheating.

An air bubble anywhere in the cooling system will result in the same damage. A poorly fitted radiator cap allows air to enter or fluid to escape also leads to similar failures.

AVOIDING DISASTERS BY UNDERSTANDING THE NATURE OF HOVERCRAFT

March 11, 2022

Since Hovercraft are in the helicopter family, understanding the nature of hovercraft will help you avoid disasters. To learn more about the nature of hovercraft, CLICK HERE!

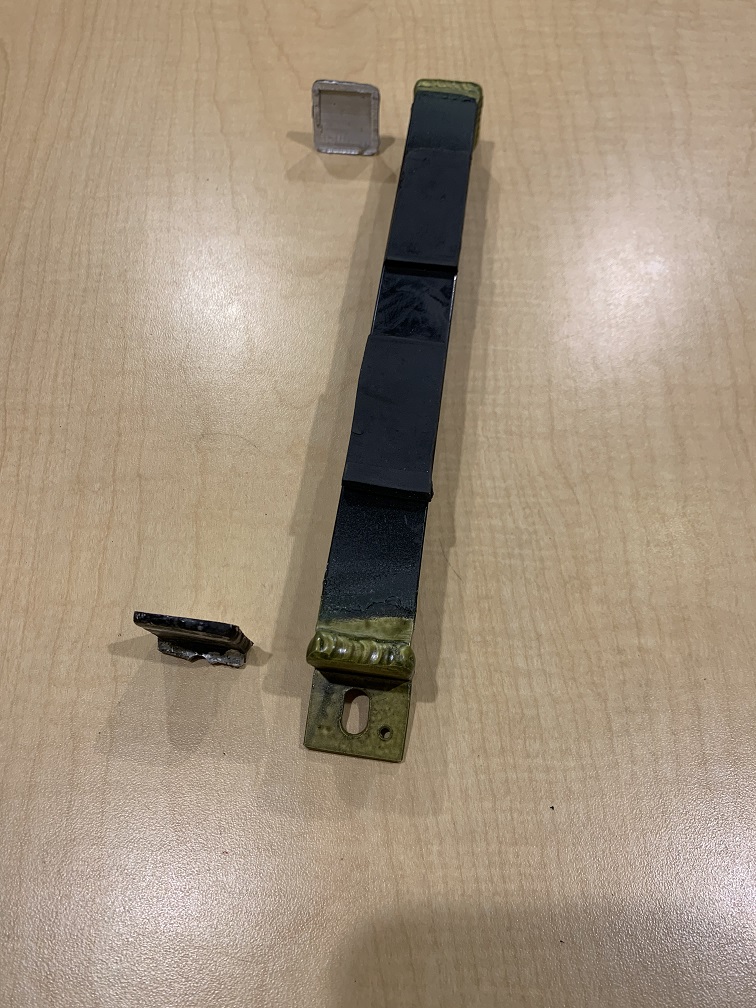

LOOSE OR BROKEN MACHINERY PARTS

Feb 4, 2022

As explained during hoverpilot and maintenance training the pre and post flight inspections must always include checking for loose bolts and parts such as spinner, bell, air box and cracks in engine mounts, fan hub or spinner clamping bracket. Wherever any cracks or loose components are discovered they must be fixed before any serious failure occurs. Two recent examples include a cracked engine mount pipe on a 55hp engine mount and a broken 100hp HT6 spinner clamp bracket which were not observed before the fan was destroyed.

The HT6 spinner clamp bracket is held inplace with two ¼ inch wing nuts safety wire tied to the bracket. Both bracket lugs failed from either being too loose or vibration of the machinery module cause the spinner to come loose and the lugs fatigued then they both broke off the bracket. With one or both lugs broken the spinner would have been noticeable loose. Either the broken lugs with wing nuts attached came off and went through the fan or the spinner clamp bracket, one or the other caused the fan to fail.

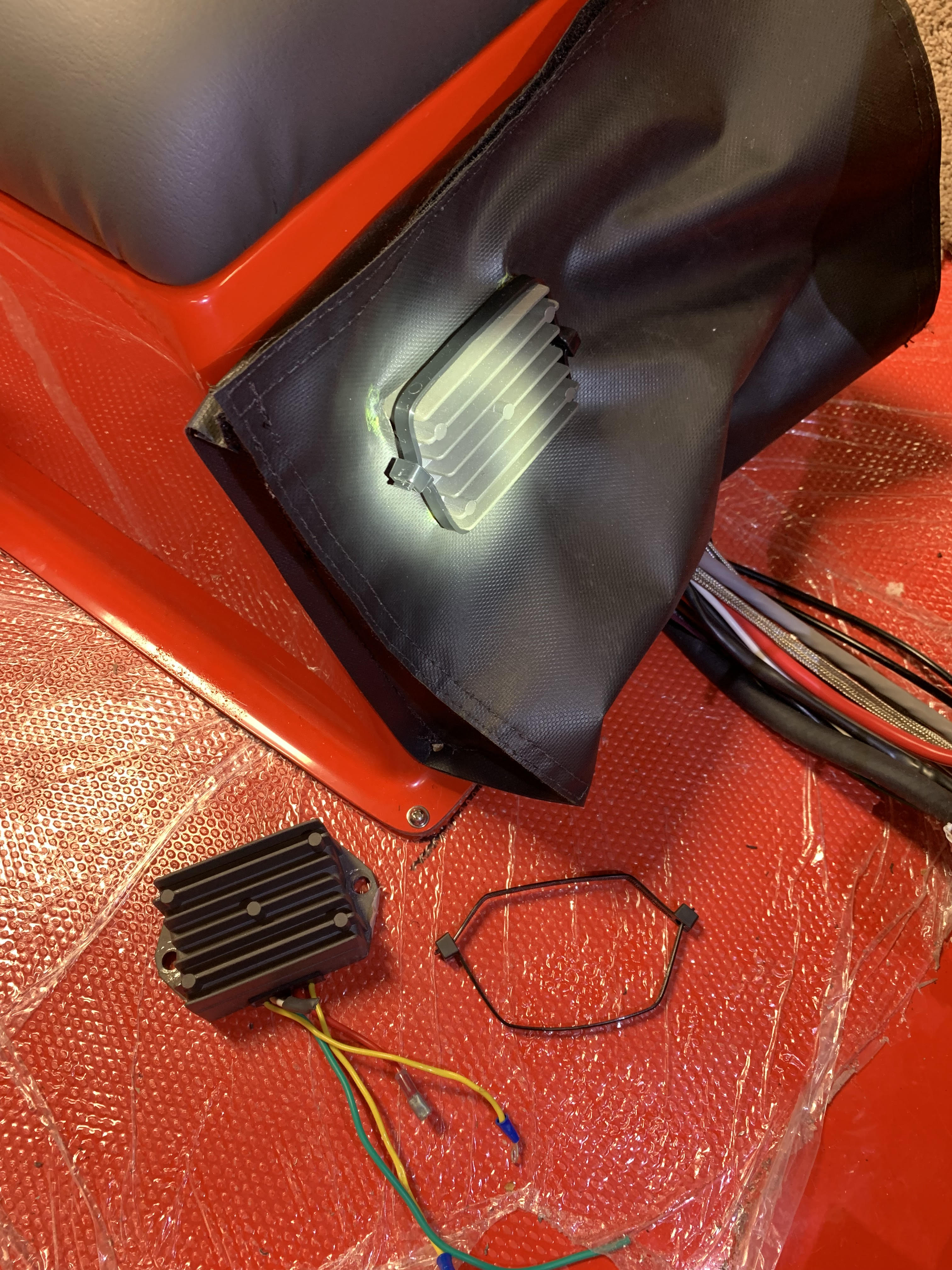

FAILING REGULATORS

Various voltage converters and regulators have been used over a period of many years. Two-cycle magnetos usually have two yellow wire outputs one from each end of the charging magneto coil. On some Fuji engines in early Neoteric Hovercraft, one yellow wire was grounded so the output was only half. On 2 wire outputs, the voltage can be anywhere between 30 to 60 peak volts AC (Alternating Current). This is a dual-phase regulator. Regulators with 1 yellow wire input are single phase regulators. We have used a 3 phase regulator modified to two phase but the current regulator is dual phase.

Our early regulators were mostly single-phase regulators but 2 phase regulators give higher charging rates usually up to 20 amps at 12+ volts which is 240 watts. The level of charging depends on the speed of magneto rotation (i.e. engine RPM).

When the Hovercraft battery is fully charged all wattage from the regulator is dumped to ground where it is converted into heat that gets radiated through the regulator fins. When there is little electric load on the charging system, the regulator reaches its maximum internal temperature so it is advisable to always run with lights on to produce an electric load.

We have been experiencing increased regulator failures and we believe they are associated with regulator overheating, which internally cooks the regulating diodes. Since the Hovercraft’s tachometer takes its speed pulse from one of the regulator input wires, the tachometer stops working if the regulator fails.

Until now regulators were enclosed inside an auxiliary mount plate neoprene splash bag. This means they have no cooling air.

A new modification entails cutting a small rectangle hole in the splash bag, 2” x 2 ¾”, and exposing the regulator cooling fins. Two 120lb Nylon ties are joined together and tightened around the regulator to prevent the splash bag from slipping off over the cooling fins. The ties can be slid off when the auxiliary mount plate has to be exposed for inspection, cleaning and fuse changing.

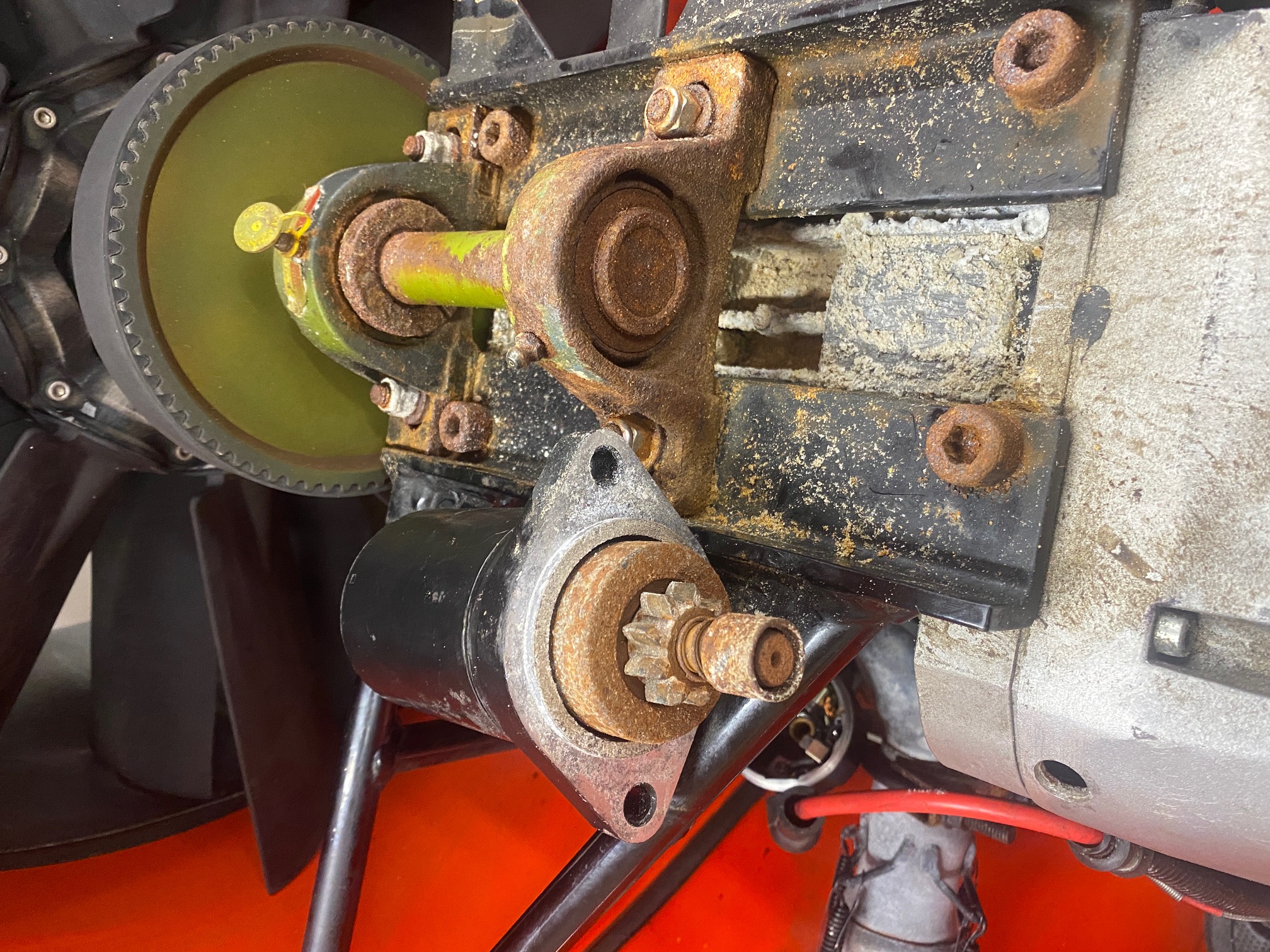

DEVASTATION CAUSED BY SALT WATER

Photo of devastation caused by Salt Water. All metal and electrical components must be thoroughly washed with fresh water. Let dry for ½ hour then spray all the same surfaces with WD 40 or a light oil. Starter Motor Bendix has a ½ oil hole which should be flushed with fresh water, let dry then squirt WD 40 and also squirt SAE 30 weight oil through hole on to the Bendix. Allow metal to dry before oiling.

Operation in Salt Water requires a robust cleaning maintenance program. If you hover for 1 hour in Salt Water you must be prepared to clean and service the machine for 2-3 hours. With this level of maintenance, the overall maintenance requirements can be managed and improved.

GEL COAT REPAIR INSTRUCTIONS

For instructions on repairing the gel coat on your hovercraft, download the PDF file below:

LONG TERM HOVERCRAFT STORAGE

When hovercraft are placed in long term storage provisions have to be made to prevent corrosion, deterioration of fuel lines and fabric materials. Ozone in the atmosphere damages rubber belts and skirts. Fuel inside primer bulbs, carburetors, and fuel lines has to be drained out otherwise the lines etc. will go hard and fail. Suggestions for preparing the engine for storage can be found in the hovercraft maintenance manual. Animal nesting inside the vehicle can cause much harm. These two photographs are an example of such damage. This is a Fuji 50HP engine used in the Neoteric Questrek model. Mud dubber wasps have built 3 nests inside the motor magneto and cooling air shroud.

Over a period of 1 year, wasps built three nests inside the magneto and one nest in the engine cooling duct. The cooling duct nest was small with little restriction of cooling airflow. Nests inside the magneto were considerable damaging.

The engine would not run even though it had good compression, spark and fuel. It would fire and backfire but refused to run. The CDI was replaced but did not help. Timing was suspect. To check timing, the engine has to be run which was not possible.

When one of the timing adjustment screws could not be seen through the magneto flywheel, the flywheel was removed only to find a wasp nest covering one of the screws!

After carefully removing the nests, the igniter coil ground wire was found to be broken. Both nests were built against the magnets in the flywheel and covered the end of the coils, one nest surrounded the ground wire.

When attempting to start the engine, the bond between the nests and the rotating magnets sheared but both nests stayed firmly attached to the end of the igniter coil. With frequent cranking and occasional short running of the engine, the nest covering the black ground wire pulled away and began to chatter and vibrate. We suspect this vibration fractured the soldered ground wire joint. Once everything was cleared up and the wire re-soldered the engine ran! This is an excellent example of the risk of long term storage without proper cocooning.

LOOSE TRAILER WHEEL

Before heading off on a long road journey be sure to check tire pressure (including spare wheel) 45 psi, check wheel nuts and bolts for correct torque, 75ftlb, and rock each wheel sideways to be sure there is slight looseness in the bearings. Its also a good idea to remove the grease cap and pack the bearings with Axle grease.

You can see from these photographs what damage results when nuts or studs come loose. Such a catastrophe can be life threatening!

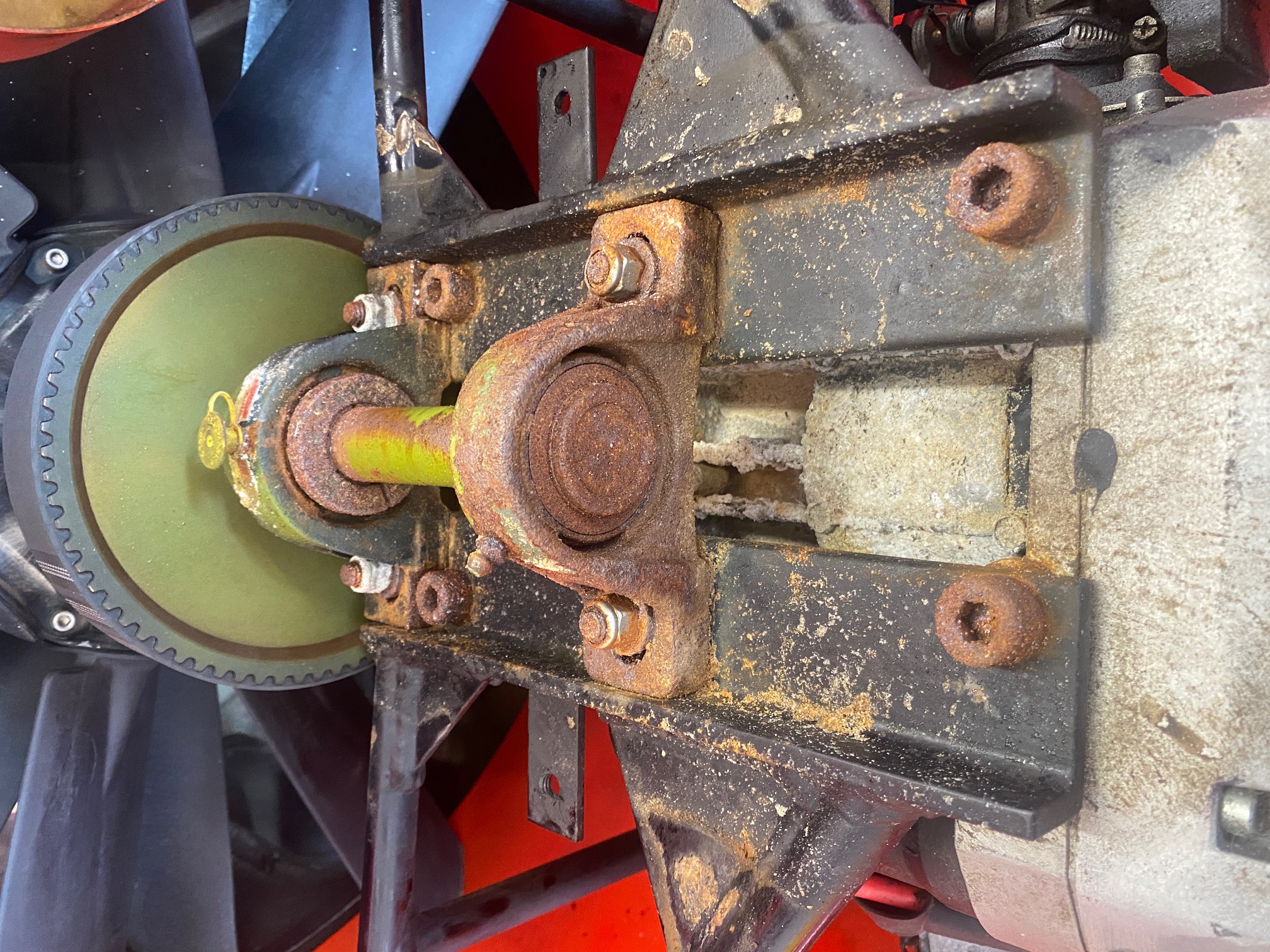

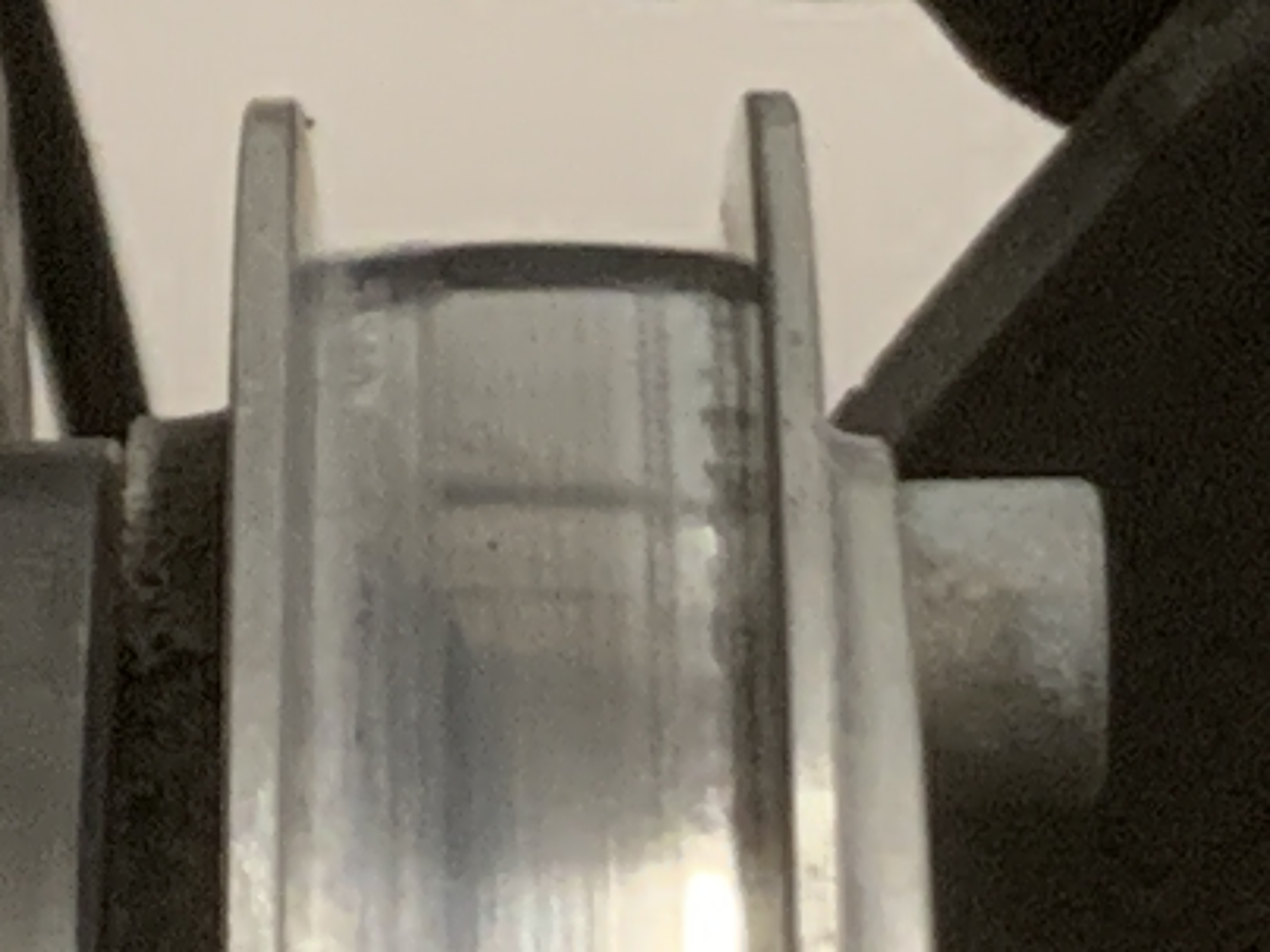

HIRTH ENGINE COOLING FAN PULLEY WEAR

Wear on Drive Pulley

This pulley has a crown "concave" shape. Wear can be seen. If wear is excessive, even a new belt will slip. So this drive pulley must be replaced. The pulley shown is worn but still has at least 50 hours of life remaining.

Wear on Fan Driven Pulley

Typical wear pattern on cooling fan pulley caused by loose belt slipping in dust and water spray environment can happen in as little as 15 hours of operation. Belt must be kept tight.

Flat belt shown below,

Poly "V" belt is newer design and gives better endurance (not shown). To repair fan pulley, return pulley to Neoteric and we machine a stainless steel sleeve to replace the worn surface. Cost is equivalent to new fan price but pulley life is extended.

MULTI-WING FANS

Multi-wing fans with taper lock bushings, used on the Hovertrek™ hovercraft, should be inspected for cracks in the aluminum hubs. On occasion, these have been found to occur after 75 hours of service. The hubs can be viewed through the gap behind the spinner. More detailed inspection requires the removal of the thrust duct. These images illustrate examples of cracking.

Loose Fan Bolts

In Dec 19, it was decided to replace the 1/4-20 SS nyloc nuts on the fan hub perimeter with 1/4-20 zinc plated hex nuts and to loctite in place. Torque to 78 in lb. Only replace the nut and do not change bolt or balance washer.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

AIR FILTER BOX RIVETS

Correct placement and tightness of hose clamps should be maintained. Fan failures can result from untightened air filter boxes which can vibrate off and enter the fan. Check hose clamps for proper placement and tightness.

An incident has been reported from a Korean fire department that operates their rescue hovercraft in saltwater. Corrosion appears to be the culprit. Galvanic corrosion occurred between the aluminum rivet head and the chrome-plated steel cap fitted to the end of the air filter.

If one rivet head fails, the rivet head and washer may enter the engine, resulting in the destruction of the engine. Neoteric strongly recommends frequent inspection of the air box as a preventative measure. These images illustrate the damage. If both rivet heads fail, a fiberglass air box cover can be released and sucked into the fan, causing significant damage.

Neoteric recommends that all craft owners drill a 3/16" [5mm] hole in the forward edge of the air box flange and use two wire ties (the same as used for skirt attachment) to secure the air box to the wire tie looped through the spark plug coil. Neoteric is currently researching all options for a long-term fix. When developed and tested, the fix will be posted here .

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

ENGINE AIR INTAKE BOX RIVETS

A report has been received of loose rivets in the engine air intake box which hold the air filters. The rivets had become worn from vibration. If failure occurs, the rivet steel mandrel head and washers can enter and damage the hovercraft's engine. Inspect the rivets to assure they are secure; if the rivets are loose, tighten them by hammering.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

BATTERY GROUND CABLES

Two customers have reported that the battery cable ground wire can break where it attaches to the engine. The battery ground cable and terminal end on your hovercraft should be inspected for cracks. If this cable should break, it could possibly result in electrical damage to the voltage regulator, reverse thrust computer, and other electronics/instruments.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

FUJI ENGINES

We recommend that the Y manifold nuts on our hovercraft powered by Fuji engines be inspected to ensure that they are tight. If you should discover that any are loose, contact Neoteric for further instructions.

We would appreciate photos if you encounter this or any other issues with your hovercraft.

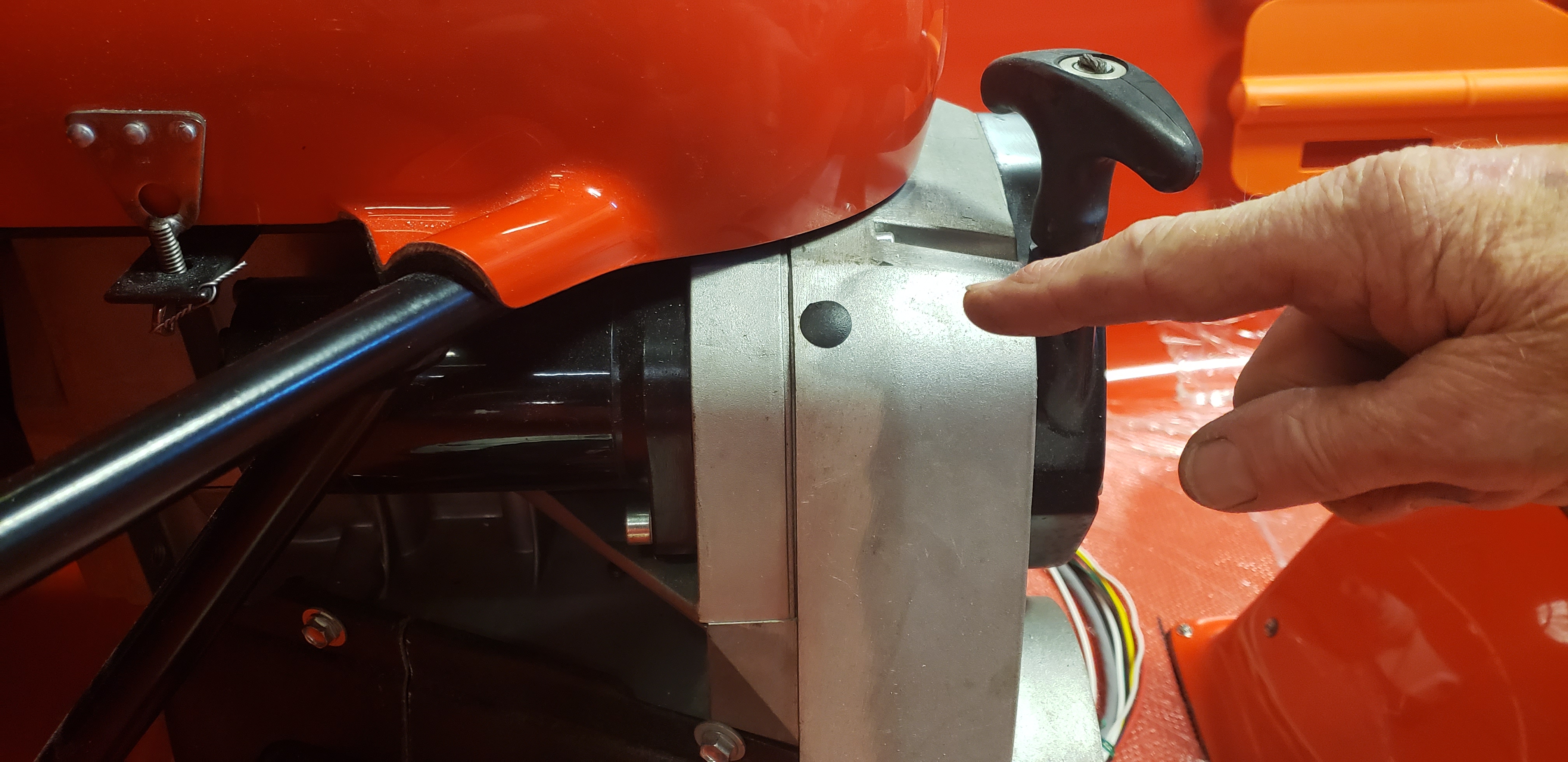

REVERSE THRUST BUCKET ACTUATORS

A few cases of reverse thrust bucket actuator failure have occurred after approximately 18 months and 50 hours of service. Intensive research has revealed that the issue is caused by ingestion of water and fine particulate matter into the actuator via the push rod seal. These ingestions could be especially damaging to hovercraft operating in saltwater. We ask you to contact us about any experiences of actuator misbehavior such as uncommanded deployment, rough or noisy operation, judder on deployment, clutch or push rod seizure and we will reply immediately with instructions for remedial actions.

Update: Neoteric has developed a splash waterproof actuator enclosure that helps prevent this issue from occurring

Part # 6405: Waterproof Actuator Enclosure

The splash cover top flange must be excessively sealed. This is more important than proper sealing of the lower and side flanges. Its advantageous to have a path for any condensation water inside the cover to leak out through the bottom seal. If for any reason the stern of the Hovercraft is submerged water can enter the Splash Cover since it is not possible to achieve a totally sealed actuator cover.

Salt water damaged actuator

ENGINE MOUNTS

Cracks can occur in the engine mounts after 75 hours of operation. These images illustrate the location and crack. To prevent this issue, inspect the horizontal support closest to the fan. Cracks usually appear adjacent to the weld zone. If repairs are in order, weld using TIG and 1/16 stainless steel weld wire.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

100HP LIQUID COOLED ENGINE PUMP DRIVE BELT

On 100 hp engines, operating in sandy or dusty conditions plus water spray may cause the water pump drive belt to lose tension and fail to drive the pump adequately.

If the belt becomes wet due to water spray and there is sand or dust grit present, even minor slippage between belt and pulley can quickly grind the metal surfaces, resulting in complete loss of drive tension. To minimize slippage, the drive belt must be tight at all times and regular checks are essential. As a field guide to correct tension, if the water pump pulley can be rotated by hand and the engine and hovercraft fan turn, then the tension is satisfactory. If the pulley slips it must be tightened. If the belt tension range adjustment has been exceeded, the belt and both sprockets must be replaced.

Neoteric is currently experimenting with an electrical, centrifugal water pump. If successfull this will be offered as an option.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

THROTTLE AND RUDDER CABLE FREEZING

Certain atmospheric conditions can produce throttle and rudder cable freezing:

- Throttle and rudder cables can freeze if water is inside the cables.

- Cable end caps are not watertight thus water can enter the cable during high-spray conditions, washdown or if any cable end is submerged.

Any atmospheric condition where warm, moist air (high humidity) enters the cable, followed by freezing operating temperatures can also result in condensation and subsequent cable freezing and lock-up. - One solution to cable freezing is to force antifreeze through one end of the cable until it dribbles out the other. This must be done when any water that might be inside the cable is liquid, i.e. it’s best done in a warm environment. Moving the cable back and forth while filling also aids the process.

The antifreeze will evaporate over time and will get pumped out of the cable due to movement of the cable, so this process should be repeated from time to time depending on the severity of the freezing conditions and how frequently the cable is operated.

Many (Glycol) antifreeze solutions are messy, toxic and can promote corrosion so should be treated with caution (use gloves and clean up spills).

- Neoteric has been experimenting with Glycerin (Glycerol) as a less toxic and longer-lasting antifreeze. Although a 67% Glycerin/water mix by weight will not freeze until around -52 degrees F, its viscosity is extremely high at this temparature so we are experimenting with a 50-50 mix which should not freeze at -5 degrees F while the viscosity is at more acceptable level to allow normal cable operation.

- An optional process is to fill the cable with liquid silicon. This may need to be done on an annual basis.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

TRANSMISSIONS

It is advised during the 300 hour inpsection of the transmission that the drive belt be removed and the rear fan shaft bearing and fan shaft are checked for wear. If there is looseness between the shaft and bearing both should be replaced.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

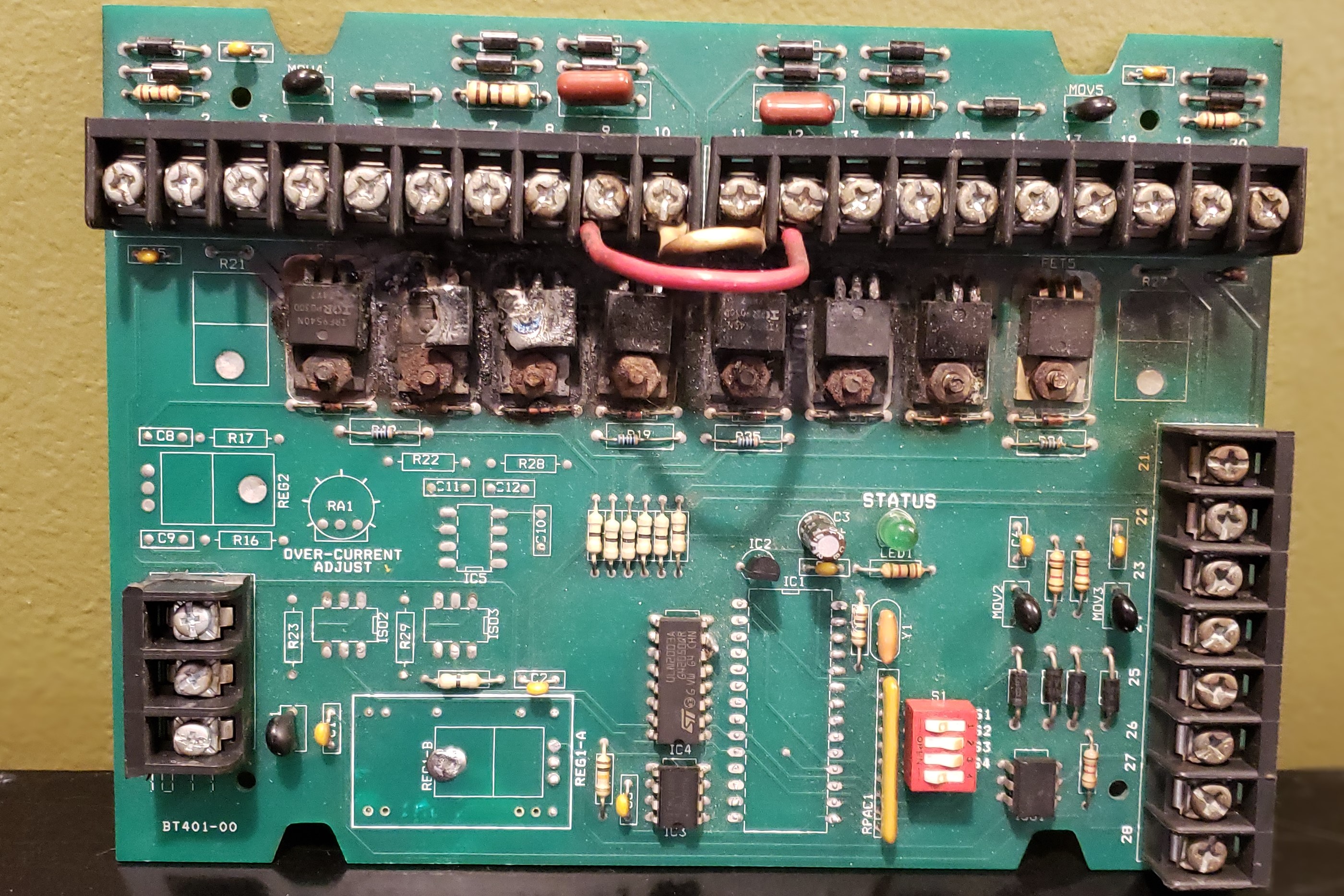

REVERSE THRUST COMPUTER

The importance of enclosing the reverse thrust computer in a waterproof metal box (Faraday cage) cannot be overemphasized. If moisture enters inside the box it can destroy the computer or cause erratic operation. Use a polysulfide caulking material to ensure that the enclosure is properly sealed.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

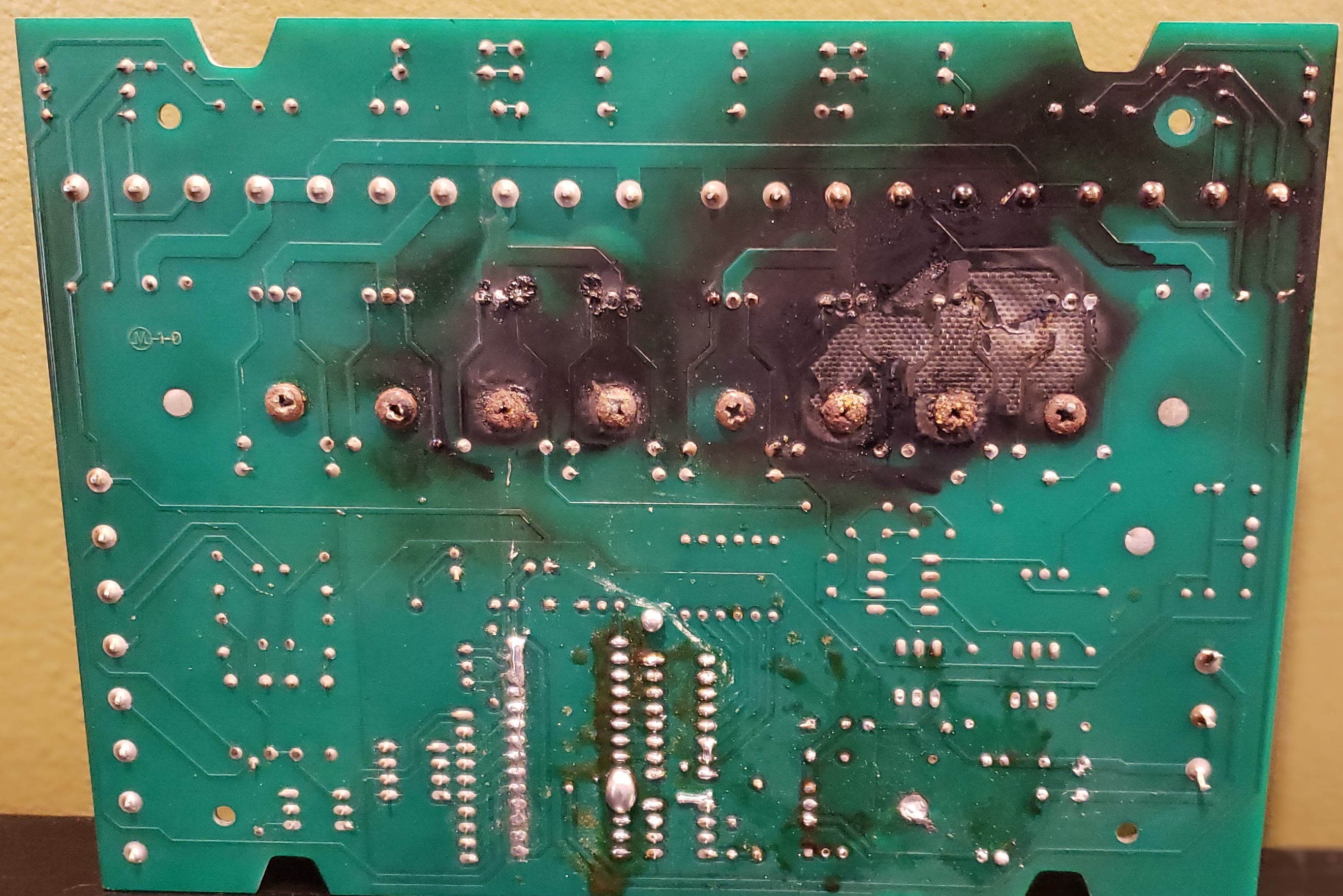

Failure of a Reverse Thrust Computer Board

Static electricity on a stalled actuator can generate a high voltage spike which can destroy the MOSFETs (small black squares). Eventually the MOSFET will fail completely; thin board shows the extent of a serious meltdown. The problem can also be the result of using jumper loads to start the engine.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

100HP ENGINE SYSTEM FAILURE

This is a failure of a 100 HP engine magneto. The cause is still completely unknown but is suspected to be caused by battery jumping.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

55HP AND 65HP VOLTAGE REGULATOR AND RECTIFIER FAILURE

Failure mode is unknown but could be internal diode component failure creating a dead short and battery feeding high amperage back through the regulator. This style of regulator is no longer used. In use now is a three phase voltage regulator of much higher efficiency. It also has a metal case so this type of burnout failure should never be seen.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

HOVERCRAFT STORAGE CAUTIONS

This is an example of damage caused by mice. This damage can often be difficult to source. In this case it took several emails back and forth before the customer found the problem. Animals have been known to build nests in exhaust systems which often can also be hard to resolve.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

SERVICING THE MACHINERY MODULE VIBRATION FOAM

This can happen when you allow the fan machinery module to run after the foam vibration collars have packed down. Foam vibration support collars need to be replaced every 100 Hrs or less.

Contact Neoteric with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.

SEA WATER RELATED FAILURE

Excessive salt water spray collects in the foam sealing the terminal block and cause a salt bridge. This leads to current leaking of disruption of engine electrics. Engine stops running. Company has a fix for this.

Contact Neoteric for a specific advice or with any questions you may have. We would appreciate photos if you encounter this or any other issues with your hovercraft.